Article No. VK-IND07

IND07 Crack depth determination (TOFD)

Crack depth determination upon an aluminum test block with defined cracks

- Subject matter of the experiment

- Theoretical and practical aspects of the experiment

- Results

- Equipment

- Related Experiments

Crack depth determination is carried out upon an aluminium test block with defined cracks. The two methods used, the echo amplitude method and the TOFD method (time of flight diffraction), are comparatively evaluated regarding their performance and detection limits.

Keywords: Non-destructive testing (NDT), sound velocity, shear waves, ultrasonic diffraction, angle beam testing, angle echo, skip distance, TOFD method, ultrasonic B-Scan

]In the fracture mechanical evaluation of components regarding two-dimensional separations (cracks) accurate information is required on the defect geometry such as crack depth, crack length and crack depth position. Surface cracks can be detected with great sensitivity with angle beam probes. In this process, echoes are searched for that occur in the angle between crack and surface. Depending on the crack size and crack depth, two different methods are used which are to be investigated and evaluated in the experiment. On a test block, a) a groove characteristic line is determined for the crack depth determination in accordance with the echo amplitude method and b) the crack depths are determined with the TOFD method (time of flight diffraction). Based on the results, the suitability and sensitivity of the two methods, as regards crack geometry, can be assessed. In addition, another crack depth estimation can be carried out and analysed by recording a TOFD B-Scan image using the TOFD probe.

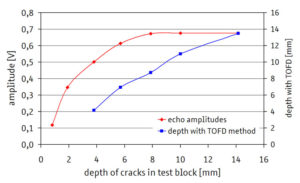

With the echo amplitude method, with the aid of an amplitude-depth characteristic line (reference block), crack depths can be estimated that are smaller than half the diameter of the transducer (8 mm). For larger cracks, the echo amplitude moves into saturation and no longer shows any crack-depth dependence. Deeper cracks can be analysed with the TOFD method. It provides no results, however, for small crack depths (1 and 2 mm). A complete crack depth test results from the combination of both methods.

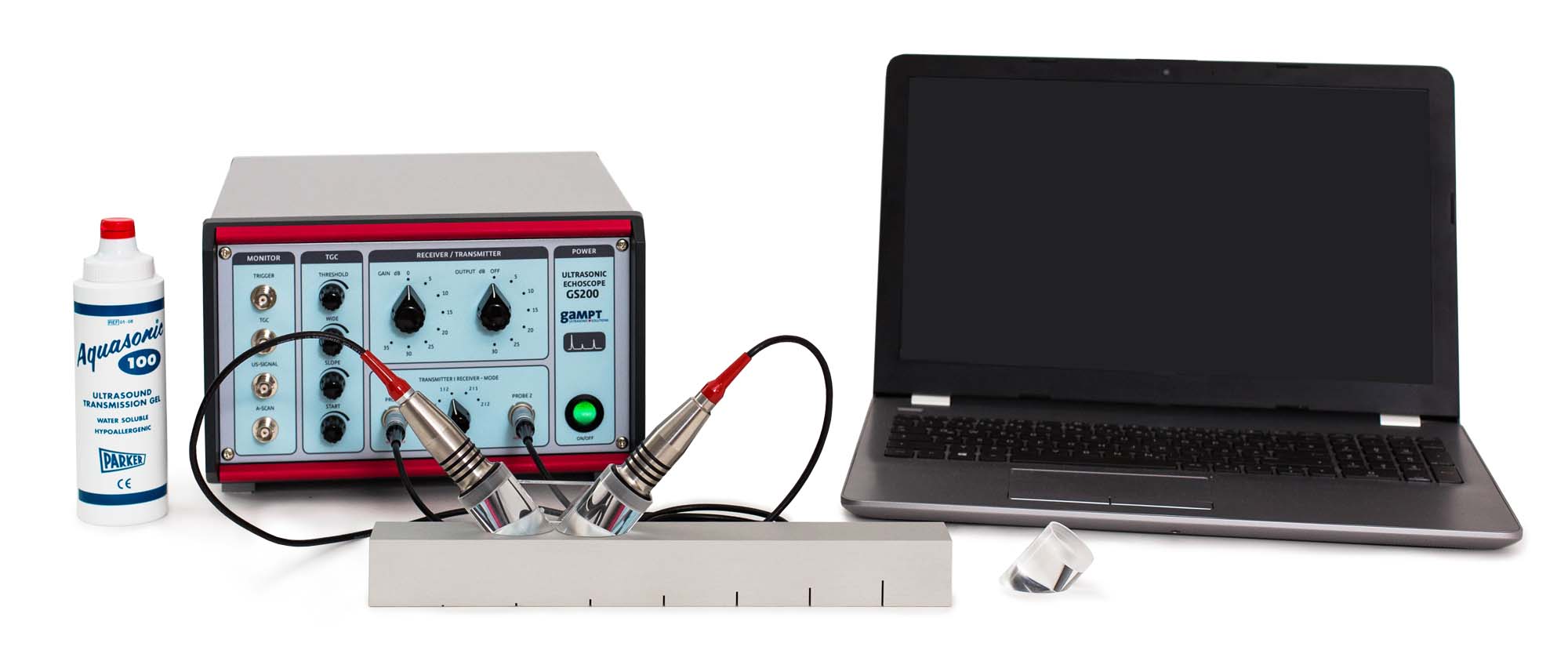

| Ord.no. | Description |

|---|---|

| 10400 | Ultrasonic echoscope GS200 |

| 10152 | 2 ultrasonic probes 2 MHz |

| 10234 | Angle beam wedge 38° |

| 10237 | Transceiver delay line (TOFD) |

| 10241 | Crack depth test block |

| 70200 | Ultrasonic gel |