Article No. VK-IND03

IND03 Level measurement

Installation of an ultrasonic level measurement for a two-phase liquid tank of any desired shape

- Subject matter of the experiment

- Theoretical and practical aspects of the experiment

- Results

- Equipment

- Related Experiments

In the experiment, an ultrasonic level measurement is built for a two-phase liquid tank of any desired shape. A calibration curve is recorded for the filling volumes and checked on the basis of a defined fill-up. An ultrasonic limit switch is tested for the maximum tank filling.

Keywords: Sound velocity, transit time, acoustic impedance, pulse echo method, initial echo, multiple reflection, continuous measurement, limit monitoring

With a large number of industrial processes, especially of the automation of industrial procedures, filling level meters e.g. at tank farms, reactors, collecting tanks etc. are required. As well as different mechanical, capacitive, optical and electromagnetic sensors, in many areas ultrasonic sensors are used for level measurement. They can be used in almost any medium, including where several materials are layered on top of each other, where there is foam formation and even in very aggressive liquids, because the measurement can be carried out from outside through the container wall. In the experiment, a level measurement arrangement is configured for continuous measurements. For two different liquids (water and oil), the minimum detectable filling level is determined and a volume calibration is carried out for each. With the aid of the calibration, a level measurement is carried out on a two-layer system of the two liquids. In addition, suitable ultrasonic signals for a limit switch are recorded and analysed.

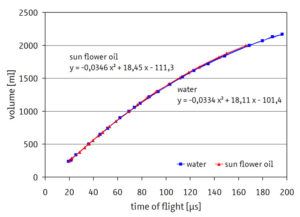

For the calibration of the level measurement, the times of flight for different filling volumes of water and/or oil were measured. To determine any filling volumes desired, calibration curves were adapted to the measurement values. Second order polynomials sufficed as curve fits. Due to the slight difference between the sound velocities of water and of the oil used, the calibration curves here have a very similar course.

| Ord.no. | Bezeichnung |

|---|---|

| 10400 | Ultrasonic echoscope GS200 |

| 10151 | Ultrasonic probe 1 MHz |

| 10310 | Tripod set |

| 10330 | Erlenmeyer flask |

| 70200 | Ultrasonic gel |