Article No. VK-30601

Bubble CounterFlowLab BCFL400 – Set Flow

Laboratory device for microbubble detection and microbubble quantification in flowing liquids

(set with one ultrasonic flow probe and accessories)

The Bubble Counter BCFL400 is based on the ultrasonic Doppler method. It is able to detect and classify microbubbles in flowing liquids down to a diameter of a few micrometers.

The flow rate can be monitored using the clamp-on flow probes.

To detect the microbubbles, the alternative clamp-on-bubble-probes (3/8″, 1/2″ or 1/4″) are attached to the outside of the tubing. The measurement is non-invasive and without contact with the liquid through the tubing material. The size, number and volume of the bubbles are continuously recorded and displayed. The system can automatically adapt to different measuring conditions (e.g. tube material, coupling, temperature influences, density of the medium).

The device is connected to a PC/laptop via USB and transfers the data in real time to the measuring and evaluation software supplied. Due to the device parameters, the measuring system is ideally suited for laboratory use. Possible applications range from component development in the medical technology/biotechnology sector (e.g. filter systems, oxygenators) to the industrial sector for monitoring and quality control of production processes.

Microbubble detection in the nl range

- Puls Doppler device with PC software

- Transmission frequency: 2 MHz

- suitable for water, water-like and low-viscosity liquids, flow velocity 0.1 up to 2.5 m/s

- measuring range 20-2000µm (depending on probe size, can also be adapted to smaller ranges on request)

for comparison: diameter vs. volume

50 µm approx. 0.06 nl

100 µm approx. 0.5 nl

1000 µm approx. 500 nl

1250 µm approx. 1 µl - non-invasive and non-contact measurement

- automatic adaptation to changing measuring conditions

- wear and maintenance-free (no disposables)

- continuous monitoring and documentation of size, number and volume of the entire measurement in real time

- CE certified

Inputs / outputs

- probe connection for bubble probes (can also be used for flow probes)

- connection for external power supply unit

- audio output

- USB port for data transfer

Possible accessories

- bubble probes for various tube sizes: 3/8″, 1/2″, 1/4″, 3/16″

- flow probes for various tube sizes: 1/4″, 3/8″

- loudspeaker for reproduction of the Doppler signal

- power supply unit

- USB cable

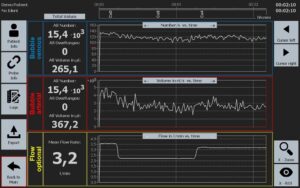

Graphical user interface

- information on status and measurement

- continuous monitoring and warning of acoustic measurement conditions

- graphical display of current bubble activity

- numerical display of current or cumulative bubble activity and / or flow

- current and cumulative bubble and volume distribution in histograms

- temporal progression of number (= number of bubbles), volume (= bubble volume), flow rate (= flow rate)

- control elements for program control

Documentation and report functions

- management of measurement data using a database

- archiving and import functions

- numerical and graphical display of the entire time course of the measurement of bubble count, bubble volume, flow rate as well as bubble sizes and volume distributions

- zoom and ROI functions for detailed evaluations

- printable measurement report as PDF

- data can be exported for further evaluation via Excel

Discover microbubbles in liquids that don’t belong there

…and that you don’t want there.

Applications in medical technology

- testing and development of components for extracorporeal circulation (e.g. filters, oxygenators)

- design and testing of HLM / ECMO

- optimization of setups

- quality management and documentation

Applications in biotechnology and industry

- protection and warning against micro-air ingress into systems

- process monitoring, documentation and quality management

e.g. for the following applications:

– paint and varnishing systems

– mixing and dosing systems

– pipetting and filling systems

– air in filter systems

– protection of pumps against cavitation due to air ingress

– hydraulic systems

– warning of foam formation

Depending on the requirements, the following are also possible

- visualization / monitoring of changes in distribution within an emulsion / mixture

- detection of clumping or dissolution of clumps (e.g. after mixing)

- device BCFL400 with power supply and software

- 3/8″ ultrasonic flow probe

- speaker with audio cable

- USB-cable

- user manual BCFL400

- quick Guide BCFL400

- calibration protocol

- transport box