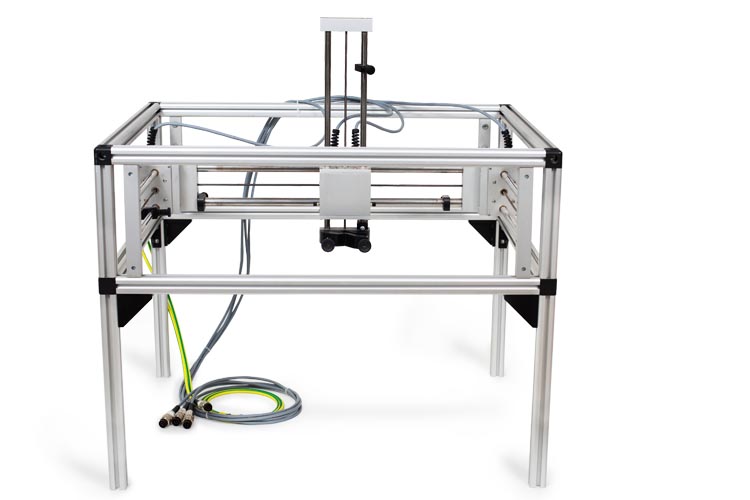

Article No. VK-62000

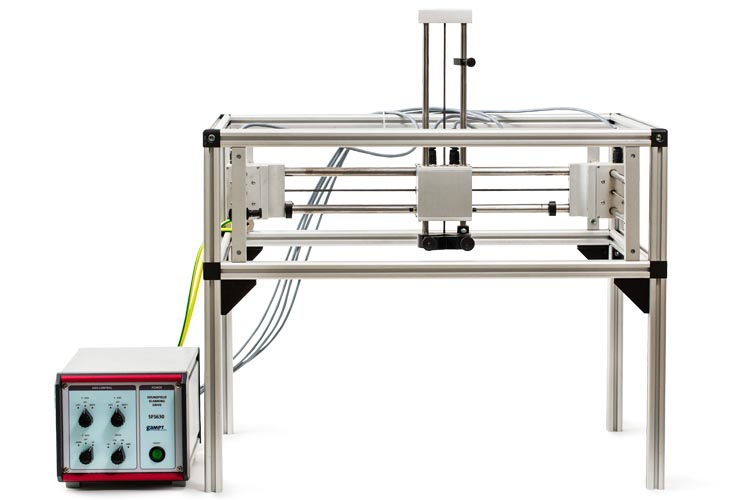

3D Soundfield Scanner

Positioning system for hydrophones and sensors

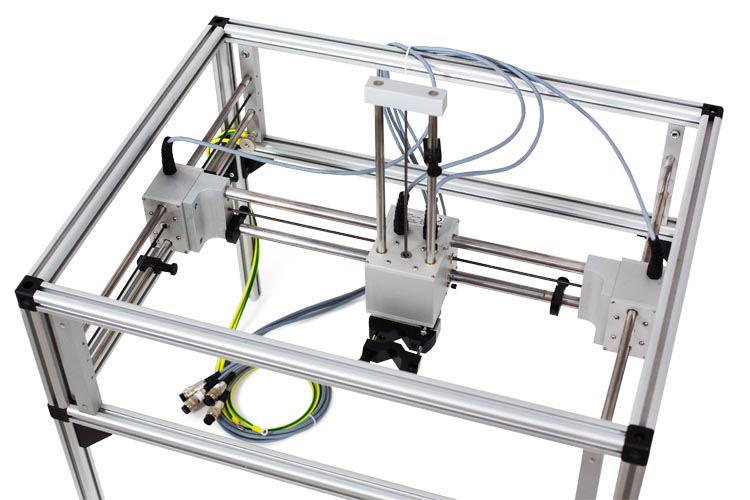

For the evaluation /estimation of the quality of ultrasonic probes the sound field geometry is important, like place and size of the focus, angle of beam of the and intensity distribution along different directions of propagation of the sound.The exact measurement of ultrasonic fields is important for the development of high-resolution diagnostic ultrasound B-image systems as well as the knowledge of the intensity maxima at high intensive therapeutic ultrasound devices (HIFU) in cancer therapy. The measurement of the sound fields is done by punctual scanning with applicable/adequate sensors (membrane hydrophone, HIFU hydrophone, thermo acoustic sensor). For the exact positioning of the sensor in the sound field GAMPT developed a 3D-scanner. With this scanner the intensities on defined points along different lines, areas and volume zones can be determined

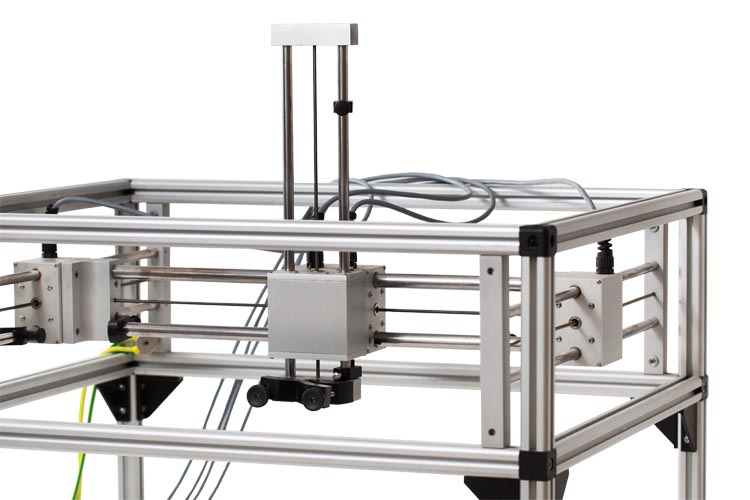

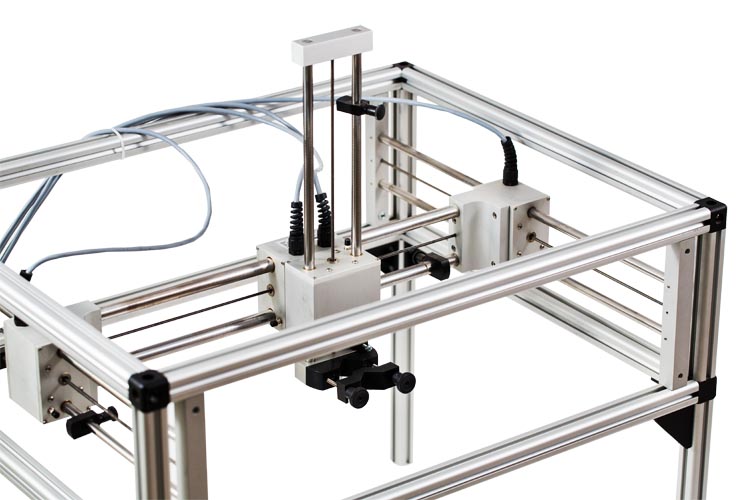

The axes of the 3D-scanner are regulated with integrated step motors and a controller. Every axe has two final position switches and can be positioned freely and separately with four different speeds using the controller. It enables a quick manual rough positioning and a fine adjustment e.g. in the focus of a sound source.To hold the measuring sensors (hydrophone, thermo sensor etc.) directly or with another stand/tripod an universal holder and various special holders and clamps are available. The ultrasonic probe will be fixed in the scanner and can be moved in it.The controller for the step motors can be connected to the PC by USB. With the provided software the scanner axes can be positioned with any speed or free defined areas can be scanned with a user chosen lateral/spatial resolution. The measurements can be made an oscilloscope.

The 3D-scanner will be mainly used to visualize the field geometry of an ultrasonic probe. Especially for complex ultrasonic sensors with dynamic focus, like in modern ultrasound diagnostics, the measurement of the exact intensity distribution is necessary for sensor development and evaluation of capacity/ efficiency. The search for and measurement of local intensity maxima is very difficult without scanning devices but important according to patient safety of ultrasonic devices.To ensure and declare the safety values according IEC 60601 for ultrasonic probes regulated by law, the use of a 3D-scanner is necessary to analyse the sound field.Additionally the scanner can be used for high resolution scanning of material samples or other objects e.g. NDT or circuits boards. GAMPTs portfolio includes also a suitable measuring reservoir and additional accessories as well as individual solutions on request

| Dimensions: | length 650 mm depth 520 mm hight 520 mm |

| Scan path: | x direction 300 mm y direction 350 mm z direction 200 mm |

| Scan speed: | maximal 6,3 mm/s (100%) minimal 0,1 mm/s (1%) |